Deciding how much inventory to purchase is a constant challenge for retailers. The pandemic surfaced this challenge, with many e-commerce sellers quickly running out of inventory as online shopping surged. Even the largest retailers with sophisticated forecasting models and negotiating power with suppliers often experience issues with under or overstocked inventory.

If you are reading this article, you are probably not the COO of a global retailer but rather the owner of a small or medium sized business. Being a small business comes with some real advantages when it comes to inventory management. Smaller order sizes can typically be fulfilled from multiple suppliers, rather than 1 or 2 mega-factories. Moreover, as a small business you can shift supplier overnight, whereas larger businesses often have sluggish bureaucracies with many layers of decision makers.

Avoid Overstocked Inventory

While many small business owners lose sleep over missed sales due to stockouts, overstock scenarios are equally damaging to your business’s financial health. The core mission of any physical goods retailer is to acquire inventory for less than you sell it for. But when you exchange cash for inventory, and that inventory is not converted back into cash through sales you can find yourself in a perilous situation.

Even if you know estimated monthly sales of your products, almost all sellers have had SKUs that become overstocked whether due to competition, defects or the product simply becoming obsolete. This situation is exacerbated when your inventory is stored at Amazon or a 3PL where it incurs storage fees. To mitigate these storage fees, you may choose to return the inventory to your home, but even if you’re willing to fill your garage or basement with inventory, simply shipping it back to you is costly.

Eliminating all instances of overstocked inventory is not a reasonable goal, and by trying to achieve this you would likely increase the frequency of stockouts and missed sales. So, it is a delicate balance, but there are a few things you can do to improve inventory management.

Backup Suppliers

If you source your inventory locally, or even nationally you start with a big advantage, but there are still pitfalls to avoid. Having a backup supplier is key. Like your business, your supplier has their own balancing act to manage. Inevitably your bestselling may become temporarily unavailable from your primary supplier. When this occurs having backups is critically important.

Moreover, it is necessary to maintain some minimal purchasing relationship with your backup supplier. Sellers often find backup suppliers but may go years without ordering from the company. When they find themselves in need of inventory from there backup, there account may be inactive or requiring pre-payment which slows the transition to the new supplier. So, maintaining at least an occasional purchasing relationship with your backup is important.

Liquidation Plan

Many sellers mistakenly believe that cases of overstocked inventory can be quickly resolved by simply lowering the sales price of the item. This may be true if your product has broad visibility on the marketplaces, but in most cases the opposite is true. Overstocked inventory is often a byproduct of low visibility, in other words your product listing appearing on page 7 of Amazon’s search results. If your product has this visibility problem, you could discount as much as 90% or more and see little or no increase in sales velocity.

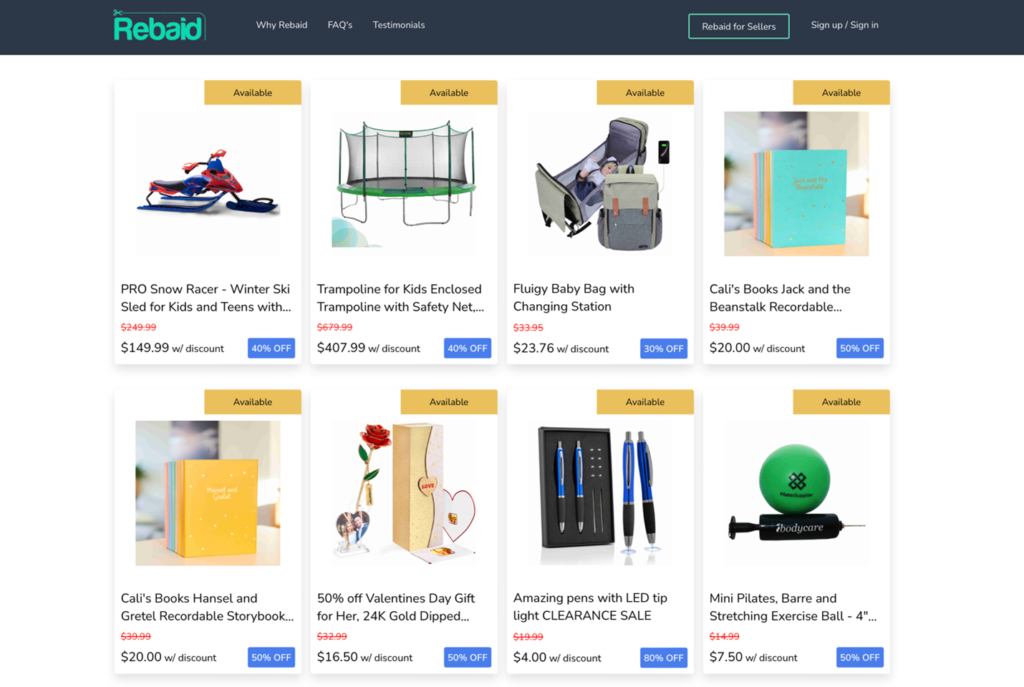

Offering a more modest discount while simultaneously resolving your visibility problem is the best way to efficiently turn excess inventory back to cash. Platforms like Rebaid.com make this easy by advertising discount and rebate promotions to hundreds of thousands of shoppers who visit Rebaid every month. Simply create a discount code of offer a cash back rebate to shoppers on Rebaid and your product listing will generate lots of traffic and sales. To aggressively liquidate you’ll need to offer a higher discount amount while mild to moderate overstock scenarios can usually be resolved with lesser discounts.

Conclusion

The most important thing to understand when it comes to inventory management is no business gets it perfect. Avoiding frequent stockouts or overstocks is the goal, but occasional inventory imbalances are just part of doing business. As your business gets larger it is worth exploring low-cost inventory management tools that can further optimize inventory levels, but this is not a substitute for mitigation plans. While we all hope that another pandemic like event will not occur in our lifetimes, there will inevitably be other unforeseen supply chain disruptions. Being prepared for this eventuality is important and provides an opportunity to establish your business as a reliable source of products for shoppers.